Power float

A power float is a hand-operated machine used to produce a smooth, dense and level surface finish to insitu concrete beds. Power floating eliminates the time and materials needed to apply a finishing screed and is quicker and less labour-intensive process than hand trowelling.

Power floats have an electric motor or petrol engine fixed over a circular pan or skimmer which smooths concrete before hardened steel reversible metal blades rotate at up to 150 rpm over the surface to create a hardened finish.

Before power floating the concrete must be left to partially set, having been leveled and tamped. The amount of setting time necessary before power floating will depend on variables such as; air temperature, humidity, the specification of the mix and so on. A rough guide for considering when to begin power floating is when walking on the surface leaves indentations of 3-4 mm. If the concrete is too wet the machine will tear up the surface, and if it is too dry, it will not be possible to trim high spots or fill low spots effectively.

Floating usually starts at one end of the slab and moves to the other. The operator holds the float at waist-height and moves backwards so that the float removes their footprints. The speed should be slow and consistent.

Once the surface has been floated, the blades are angled to suit the concrete and achieve the specified finish. Blade angles of around 5-10 degrees are usual, but these may need to be increased after each pass over the surface.

[edit] Related articles on Designing Buildings Wiki

- Breaker.

- Cement.

- Compressed air plant.

- Concrete.

- Concrete vs. steel.

- Concreting plant.

- Laser screed.

- Screed.

- Tremie.

- Types of floor.

- Types of flooring.

[edit] External references

- Speedcrete - Power floating tips

- ‘Building Construction Handbook’ (6th ed.), CHUDLEY, R., GREENO, R., Butterworth-Heinemann (2007)

Featured articles and news

Twas the site before Christmas...

A rhyme for the industry and a thankyou to our supporters.

Plumbing and heating systems in schools

New apprentice pay rates coming into effect in the new year

Addressing the impact of recent national minimum wage changes.

EBSSA support for the new industry competence structure

The Engineering and Building Services Skills Authority, in working group 2.

Notes from BSRIA Sustainable Futures briefing

From carbon down to the all important customer: Redefining Retrofit for Net Zero Living.

Principal Designer: A New Opportunity for Architects

ACA launches a Principal Designer Register for architects.

A new government plan for housing and nature recovery

Exploring a new housing and infrastructure nature recovery framework.

Leveraging technology to enhance prospects for students

A case study on the significance of the Autodesk Revit certification.

Fundamental Review of Building Regulations Guidance

Announced during commons debate on the Grenfell Inquiry Phase 2 report.

CIAT responds to the updated National Planning Policy Framework

With key changes in the revised NPPF outlined.

Councils and communities highlighted for delivery of common-sense housing in planning overhaul

As government follows up with mandatory housing targets.

CIOB photographic competition final images revealed

Art of Building produces stunning images for another year.

HSE prosecutes company for putting workers at risk

Roofing company fined and its director sentenced.

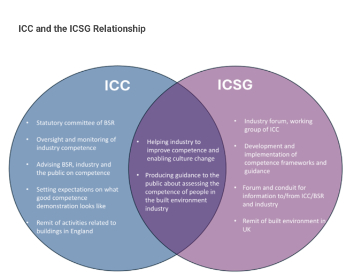

Strategic restructure to transform industry competence

EBSSA becomes part of a new industry competence structure.

Major overhaul of planning committees proposed by government

Planning decisions set to be fast-tracked to tackle the housing crisis.

Industry Competence Steering Group restructure

ICSG transitions to the Industry Competence Committee (ICC) under the Building Safety Regulator (BSR).

Principal Contractor Competency Certification Scheme

CIOB PCCCS competence framework for Principal Contractors.

The CIAT Principal Designer register

Issues explained via a series of FAQs.